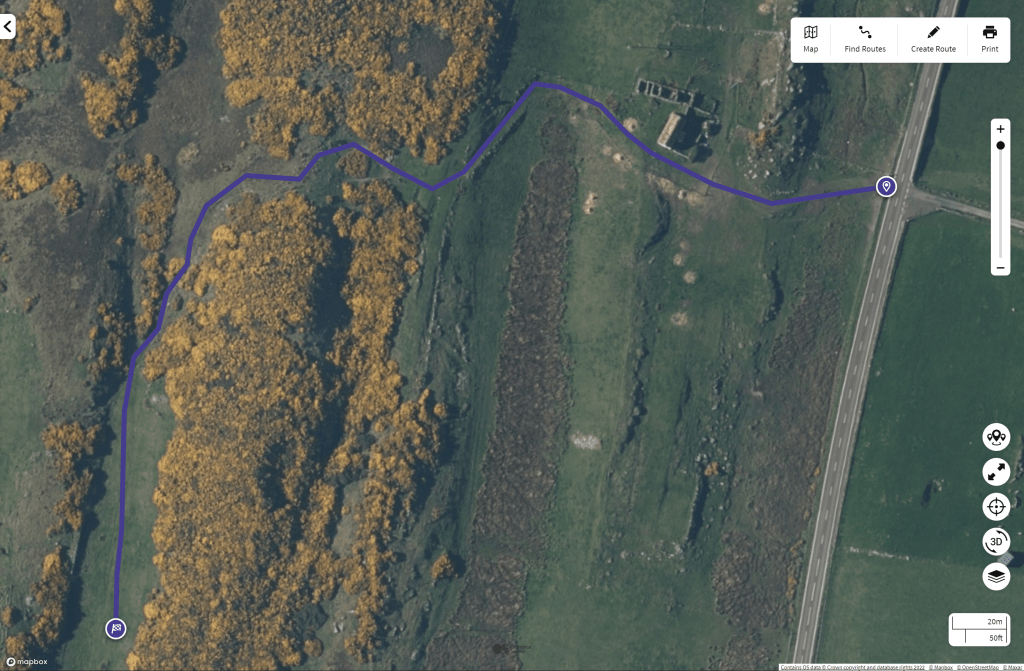

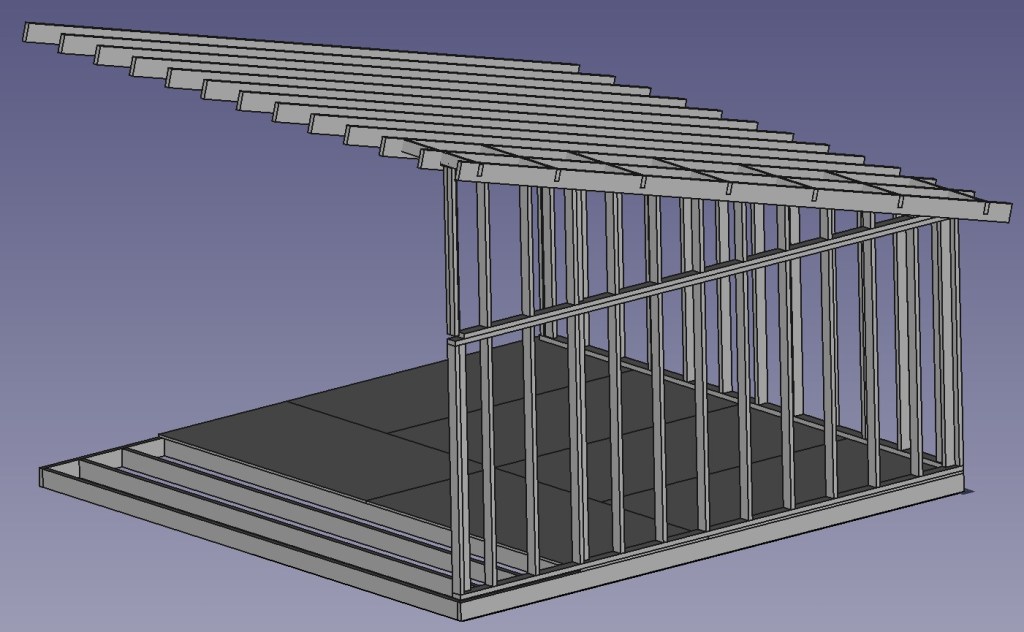

The foundation works for our barn are progressing, so hopefully the barn will be finished by the end of the year and we can start setting up a workshop – and our main electricity installation.

Last year, when I did a rough planning of our electricity needs and installation I decided to go for a battery system from Pylontech or BYD. But now, it is very hard to find a reseller or dealer that can actually deliver these batteries in the UK.

So our current plan is to “build” the batteries ourselves. And thanks to Stuart Pittaway (support him on Patreon, he created the DIYBMS) I found Fogstar, a company that imports and sells Eve battery cells. And this is where I ordered my 112 Eve 3.2V 280Ah 0.5C cells – to be delivered in late November (hopefully).

In the following sections I will explain why I ordered these cells and how I will connect them. So let’s start …

The generator

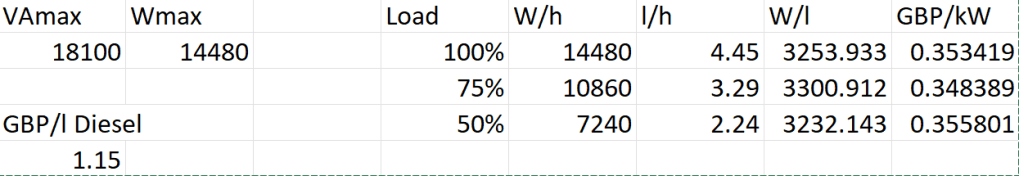

Our system will be completely off from the main electricity grid. We only have a JCB G20QS as a backup generator that can produce a constant power of 20kVA or 14.4kW. Running this generator at around 75% capacity is the most energy efficient way and will consume roughly 3.29 l per hour. This means I will have an output of 10.86kW and get a 3.3kW per litre of diesel.

The load

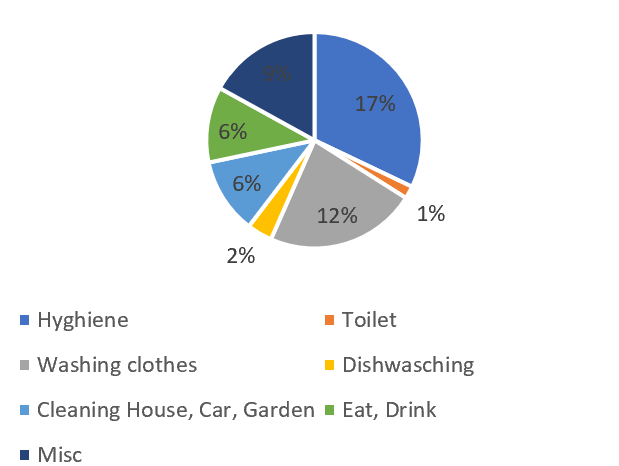

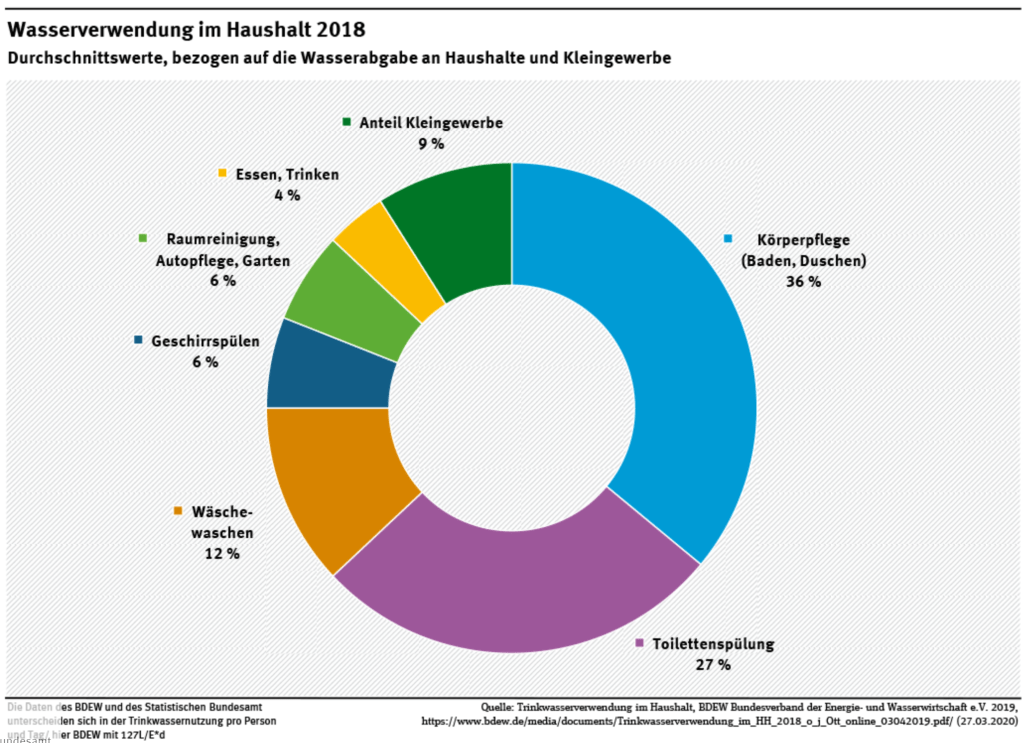

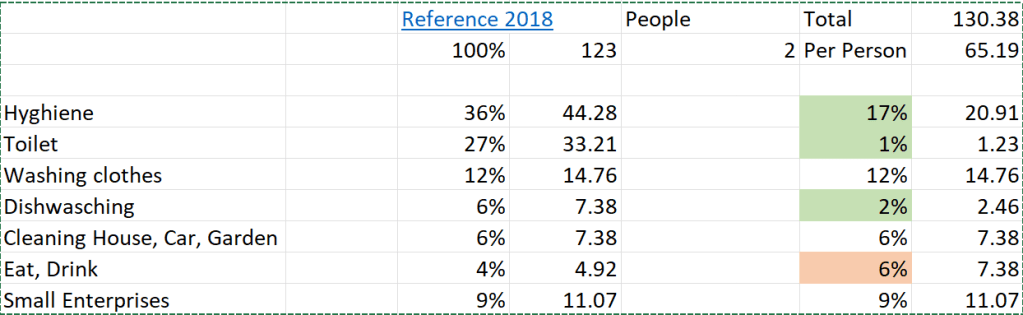

Despite my previous thoughts I will run the whole system on a single phase. This is due to the nature of “electric showers” in the UK all being single phase and using power between 8kW and 10.5kW. As I will use eneergy from the batteries for heating as well, I plan for a daily power consumption of 16kWh per day with a peak consumption of 12kW.

The batteries

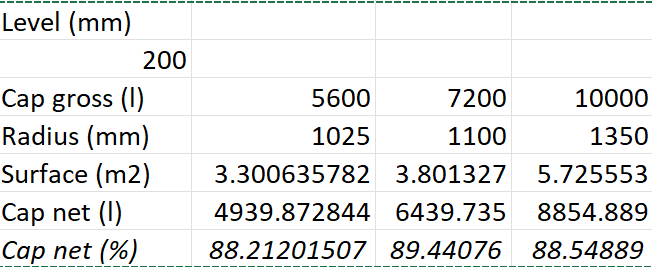

I want to be able to run at least 3 days completely on batteries, resulting in a storage capacity of 48kWh to 64kWh.

Currently available LiFePO4 cells range between 280Ah and 320Ah and have normally a C rating of 0.5C. So if use 4 parallel batteries with 16 280Ah cells each I will end up with a capacity of 4* 16 * 3.2V * 280Ah = 4 * 14’336 VAh = 57’344 VAh.

The maximum current draw would be 4* 140A = 560A with a resulting available power between 28’672VAh and 22’400VAh (when the cells run at 2.5V just before shutting off). As it is hard to find DC breakers for that current rating, I actually restrict the maximum draw to 125A per battery giving me a draw of maximum 500A and a resulting available power range between 25’600VAh and 20’000VAh. This will give me at least 16’000Wh.

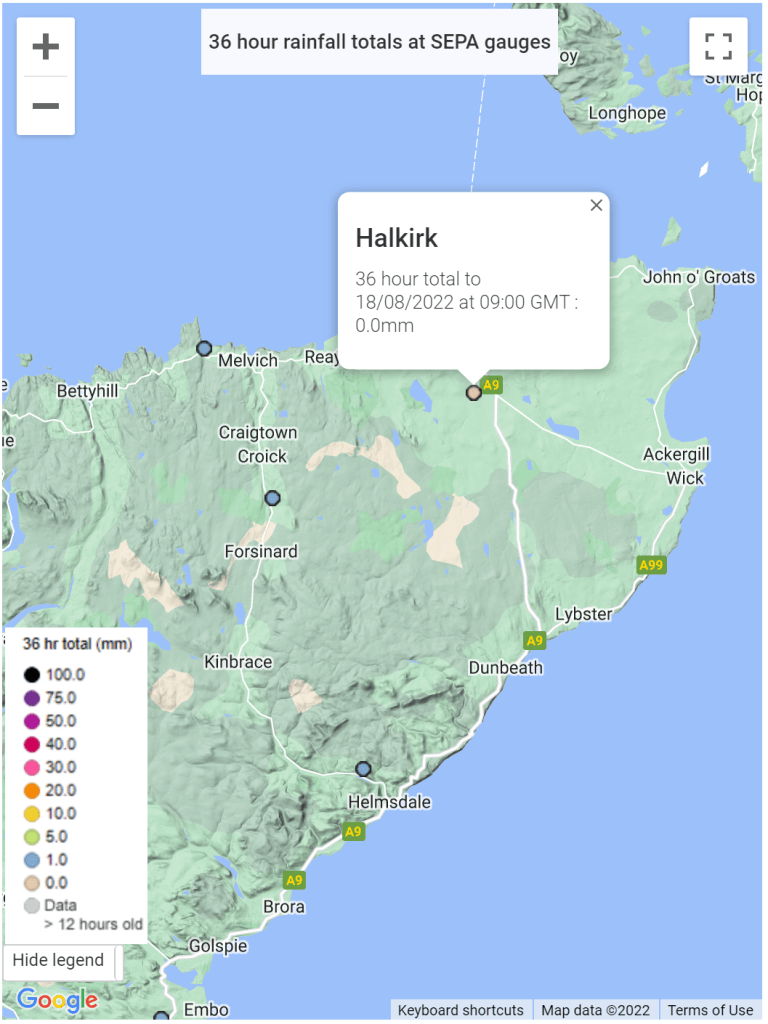

Side note: I was not sure, if I should really go for LiFePO4 batteries, as I do have the space and storing weight is not a problem either. But in the end I opted against lead acid batteries as the LiFePO4 has become so much cheaper. Temperature is not a problem for me in Scotland as it does not really get cold and the batteries are not outside below 5°C.

Each 16s battery will be controlled by a JK BMS with a 2A active balancer that is connected via RS485 to a Victron Cerbo GX (see below “The connections”).

And the main reason why I went for the 280Ah cells (instead of bigger ones) is, that

- ( a ) I do not need the bigger capacity of 4 batteries with larger Ah, and

- ( b ) I see the remaining power of the system, when one battery is offline, as too little with a 3 battery system (instead of a 4 battery system), and

- ( c ) I would need bigger circuit breakers (with the 304Ah cells), and

- ( d ) I can still draw 15’000VA with only 3 batteries on the 280Ah setup.

So the whole system is wired as a 4p16s system (instead of a 16s4p). Or was it the other way round? I always mix it up …

The inverters

I will use 3 parallel connected Victron MultiPlus II 48/5000/70-50 inverters that can deliver a constant power of 15’000VA or 12’000W (and peak up to a total of 27’000W).

One good thing about the model 5000 inverters is that they are relatively energy efficient (rated at 96%) and use only 18W per inverter. So during normal operation I might be running only 2 inverters at a time (with 36W), but I can easily add the 3rd inverter (with a total 48W). And given the output the batteries I could also add a 4th inverter later, if I really needed more peak power without having to add another 16s battery.

The connections

For this system I will use the Victron Lynx DC distribution system that is rated for 1’000A. The main fuse in the Lynx Shunt VE.Can (which is also rated for 1’000A) will run with a 500A fuse. The shunt itself is necessary as the Victron Cerbo GX controller cannot handle more than a single BMS. The shunt will tell the GX via the CAN bus the load level of the 4 batteries and thus hiding the individual batteries from the GX.

The individual BMS will be connected via RS485 and the dbus-serialbattery driver.

The Cerbo will be able to start and stop the generator based on its configured thresholds via one of its relays.

And I could always add a Victron GlobalLink 520 to it to remotely monitor the system.

Charging

Charging will be done via the 3 MultiPlus inverters where each inverter can handle a 70A. This is slightly under the 212A that the generator can produce at 75% load (see above).

This means we would theoretically run the generator for 320min to charge all 4 batteries completely (needing roughly 17l of diesel).

If we only used the generator to charge the batteries for the whole year, we would end up with around 540h of running the generator, costing us 2’040GBP (at a current price of 1.15GBP per litre).

Side note: Though the generator is able to run constantly 24/7, the service package covers an 800 h per year. So even with these 540h we are well below this threshold.

Discharging

As already written, I restrict the discharge per battery to 125A, but the realistic discharge current should be between 75A and 98A per battery on full load (so I could actually also use a 100A DC circuit breaker). These number take into consideration the loss of the inverter, reactive power and the minimum cell voltage before shutdown.

With these parameters we could draw 12kW for a period of roughly 3.6h.

The Eve cells claim to have a lifetime of 5’000 cycles. With the estimated power consumption of 16’000W per day, we would end up in 102 full cycles per year and have a theoretical life time of over 49 years. Probably not …

Accessories

As the battery of the generator runs on 12V there will be a 48V/12V charger that will take power from the main batteries and keeps the generator charged.

In addition, I will have a direct 48V connection for additional 48V portable power packs that can be charged from the main battery system.

Scalability

The inverters can be scaled up to 6 parallel systems with a maximum power delivery of 24’000kW. But even better, I could easily change the whole system to a 3-phase system and still scale it up, uilising 3, 6 or nine inverters if needed.

And the batteries could be scaled easily to 8 parallel batteries before hitting the 1’000A rating of the bus bars and the shunt.

The Lynx Power In and the Lynx Distributor can each easily be extended to support more inputs and outputs.

And if we went for a bigger bus bar, we could also replace the Lynx Shunt with a Victron 2000A SmartShunt.

Summary

So this is it. Until the cells have not been delivered I will not know if this works or not.

We will find out …

Side note: I am no Victron Shop at all, but like how their products integrate with each other and are still able to play with hardware from other manufacturers.