As we wrote previously, we installed a dishwasher – and sat it on top of our washing machine. Currently, the only place where we had space _and_ water in reach …

But operating the washing machine not astonishingly proved very unstable – at least for the dishwasher. So, we decided to create a luxurious frame to sit the dishwasher and hold in place when the washing machine was spinning.

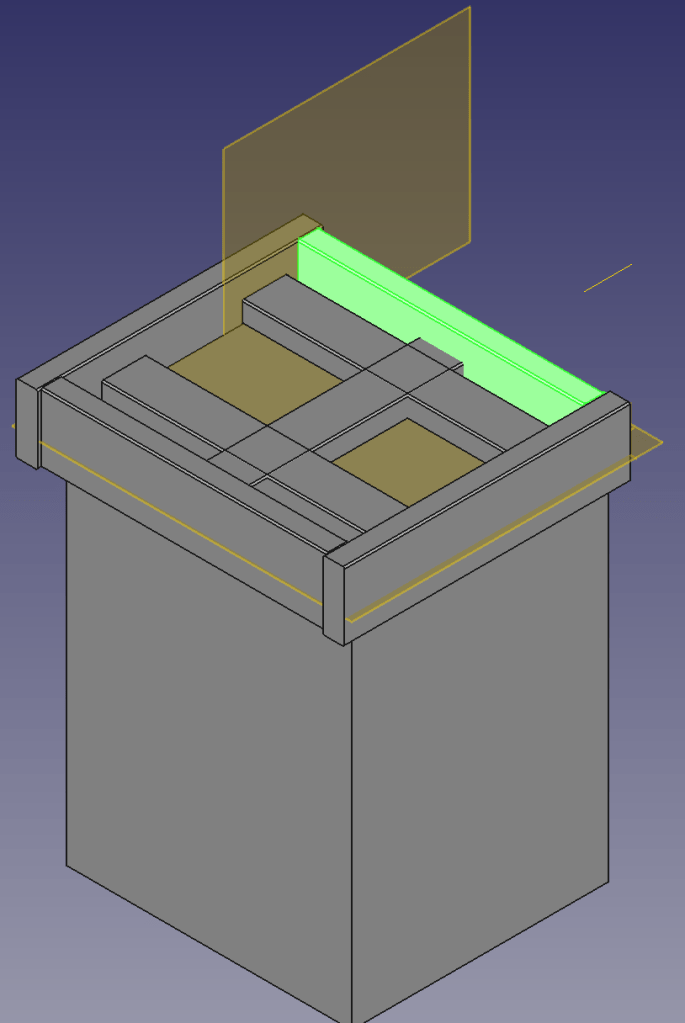

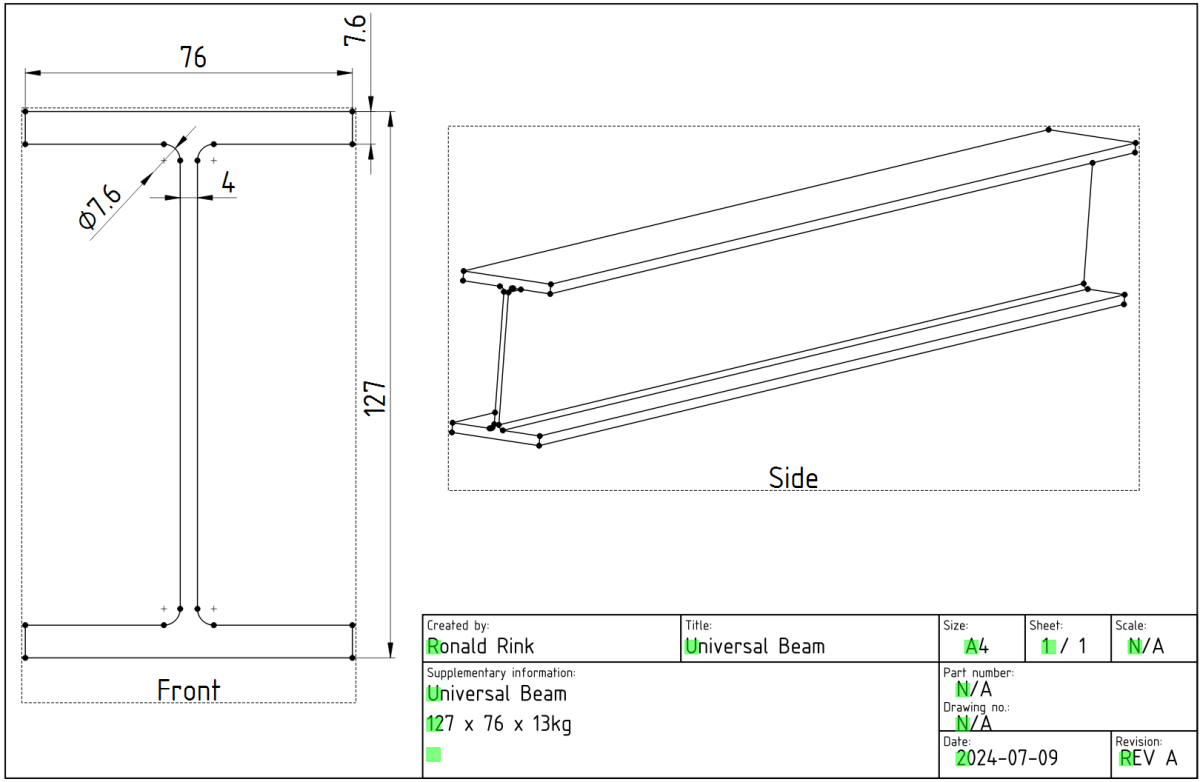

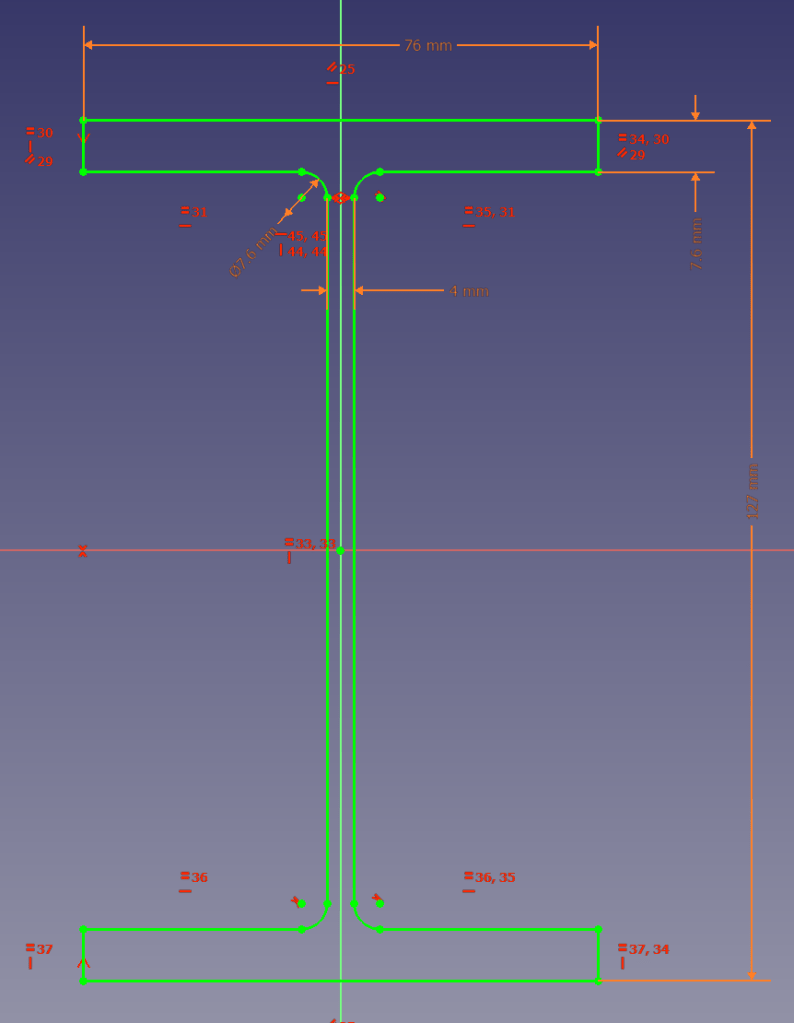

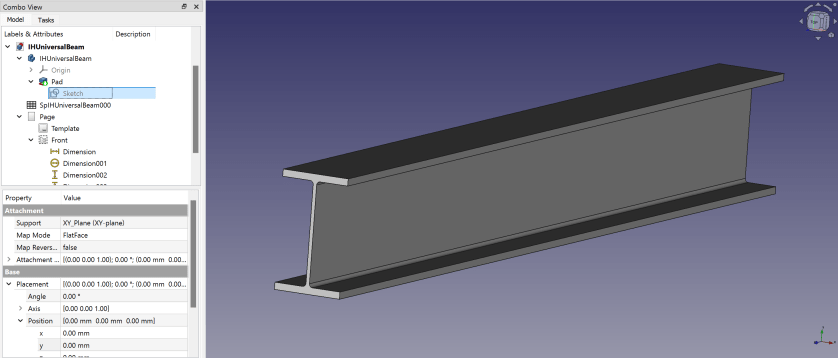

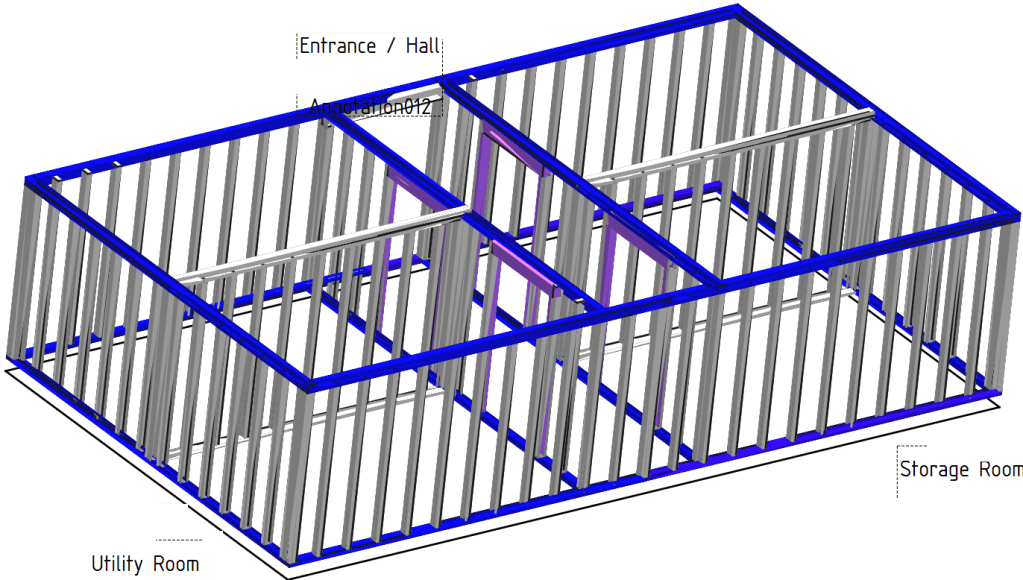

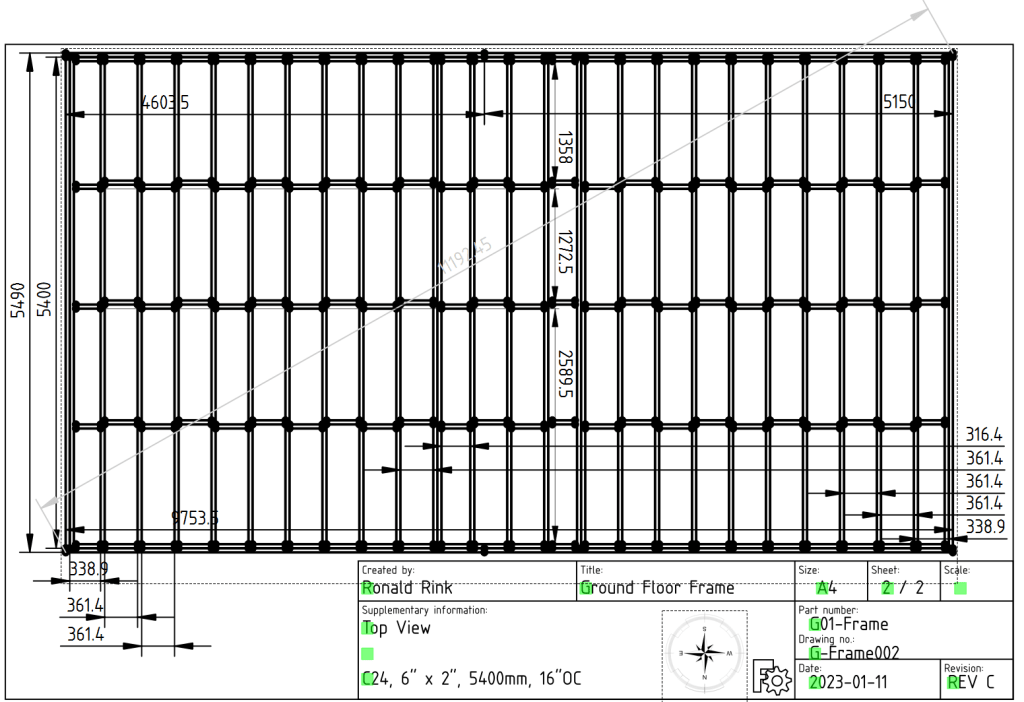

Not being agile but very waterfall, I needed a concept first. So, I fired up my trusted CAD programme and started sketching …

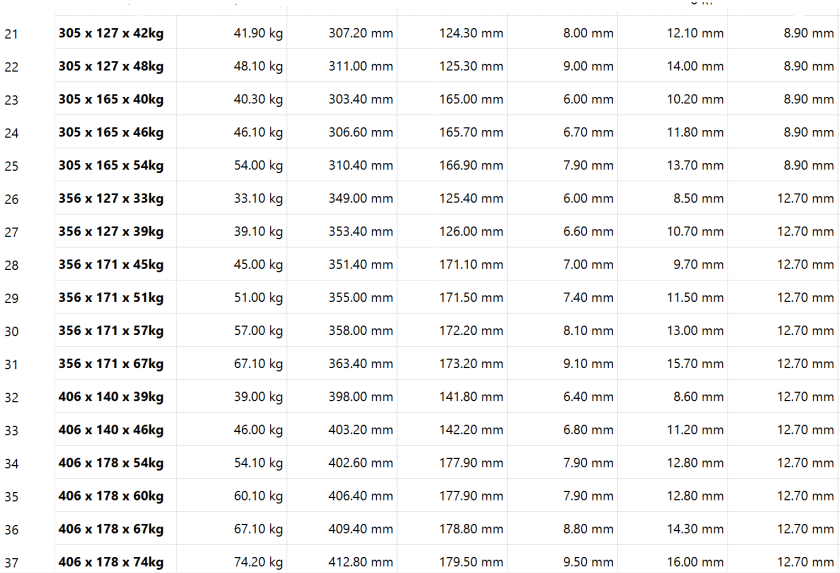

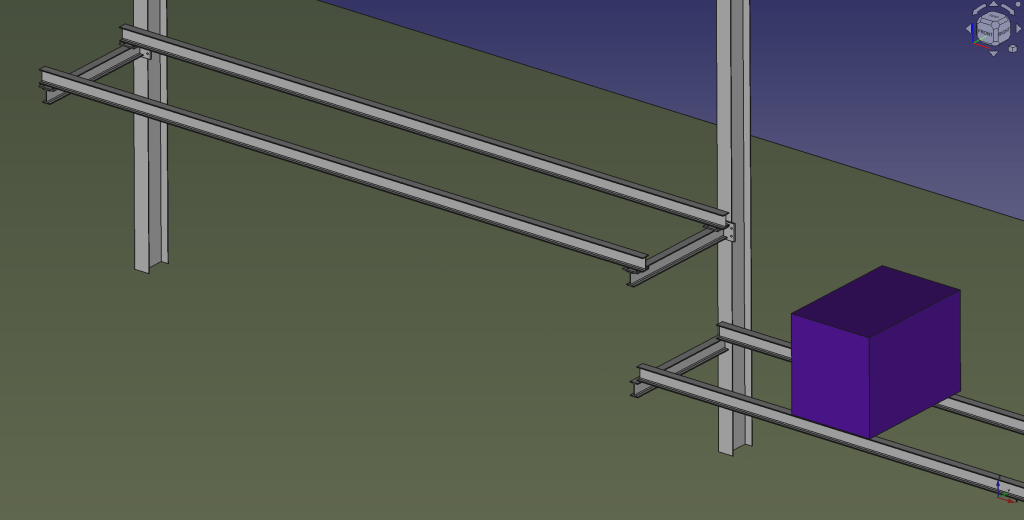

4x2s intersected with other 4x2s surrounded by 6x2s – that was the way to go.

So, first I cut the intersections of the 4x2s and used chop saw and chisel to get the cross sections.

Later on, we added 6x2s so the dishwasher would not fall off. And at the end, not visible on the images, we added a strap around both devices to stop the dishwasher from bouncing off – just in case …

Now we have a washing tower – until we move it into our new kitchen. And this is all I can tell. See for yourself.