I am not the first and probably not the last, either. With leisure batteries becoming larger and larger, fuel becoming more and more expensive and the EV charging network better and better, I thought it was time to rethink charging leisure batteries in campervans, mobile homes and the like.

For example, in UK the Tesco run EV charging stations currently offer charging at 3700W/16A at 0.288 GBP/kW. This is actually cheaper than the rates I had last year when I rented a flat. And it is still slightly cheaper than the cost of power generation with my JCB generator.

As I restrict the charging of my EVE 280Ah cells to 125A, the maximum power to charge with is either 8* 3.2V * 125A = 3200W for a 8s 24V battery or 16* 3.2V * 125A = 6400W for a 16s 48V battery. But as of now, I only plan for 24V batteries in our vehicles. This means, that even with the lowest single phase Type 2 charger in a EV charging station we get more power (16A * 230V = 3680W) than the battery can be charged with.

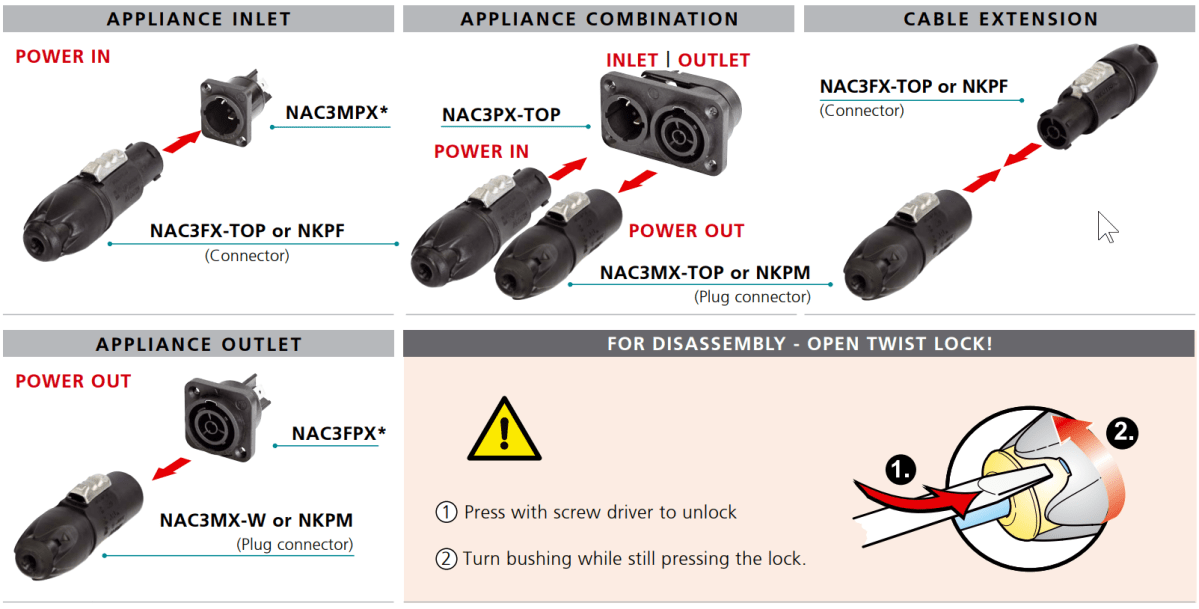

With the help from Remo Fleischli of Mobilize I found two adapter cables from Elektroscout:

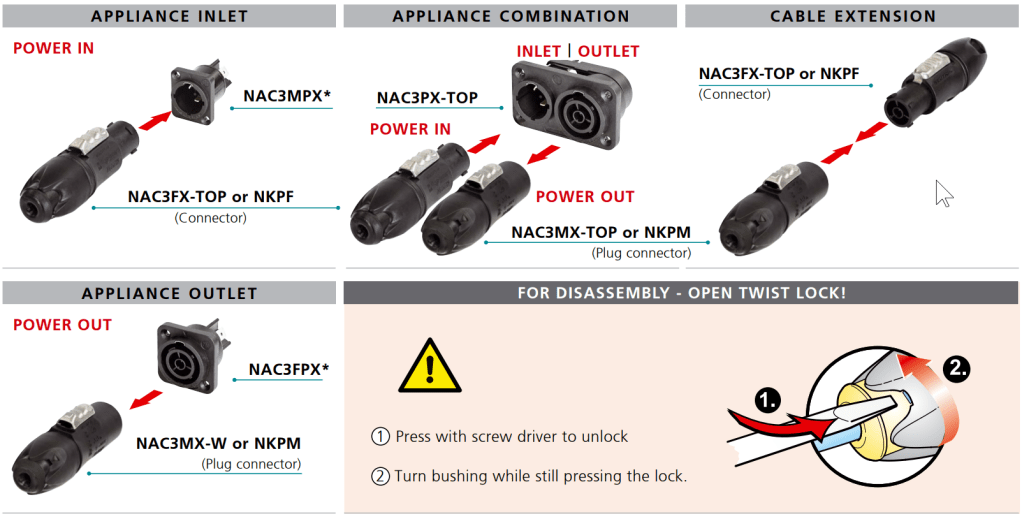

- A single phase Type 2 plug to a Swiss T23 socket, which I ordered with a “loose end” to connect a Neutrik powerCON TRUE1 TOP NAC3FX-W-TOP-L with it;

- and a single phase Type 2 socket to a Swiss T23 socket, which they call a “bike adapter” – this comes in handy at charging stations with a 3-phase Type 2 cable.

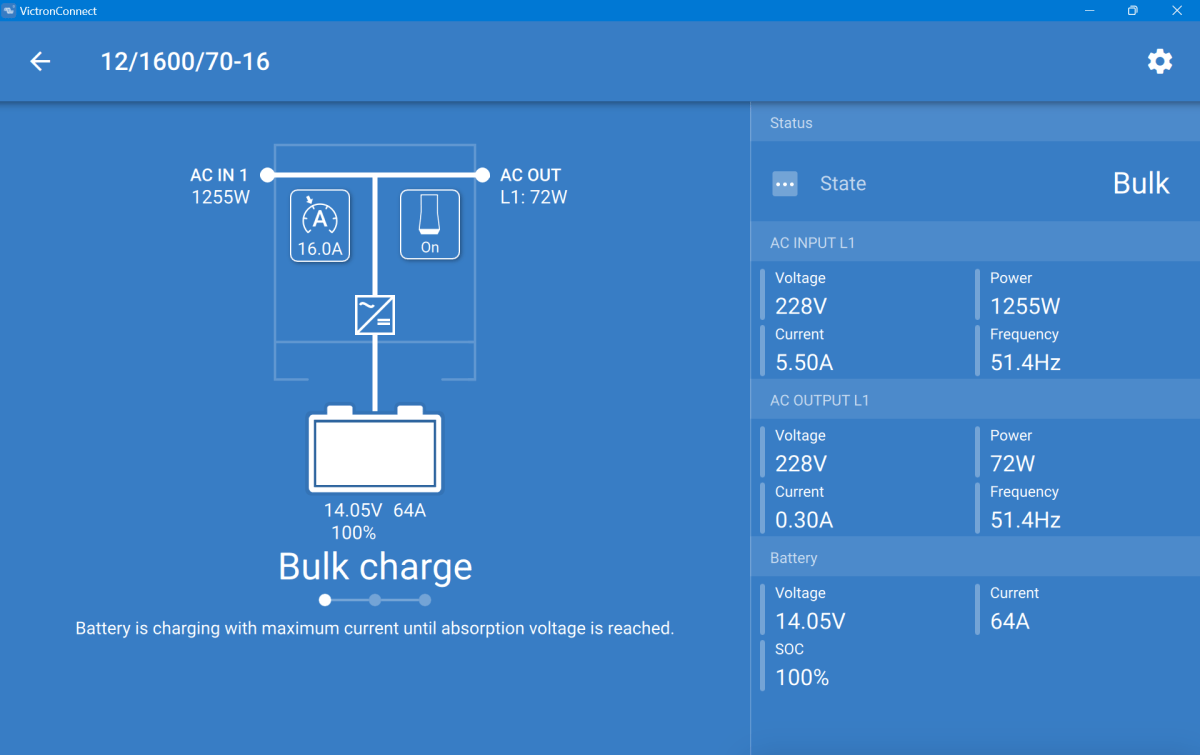

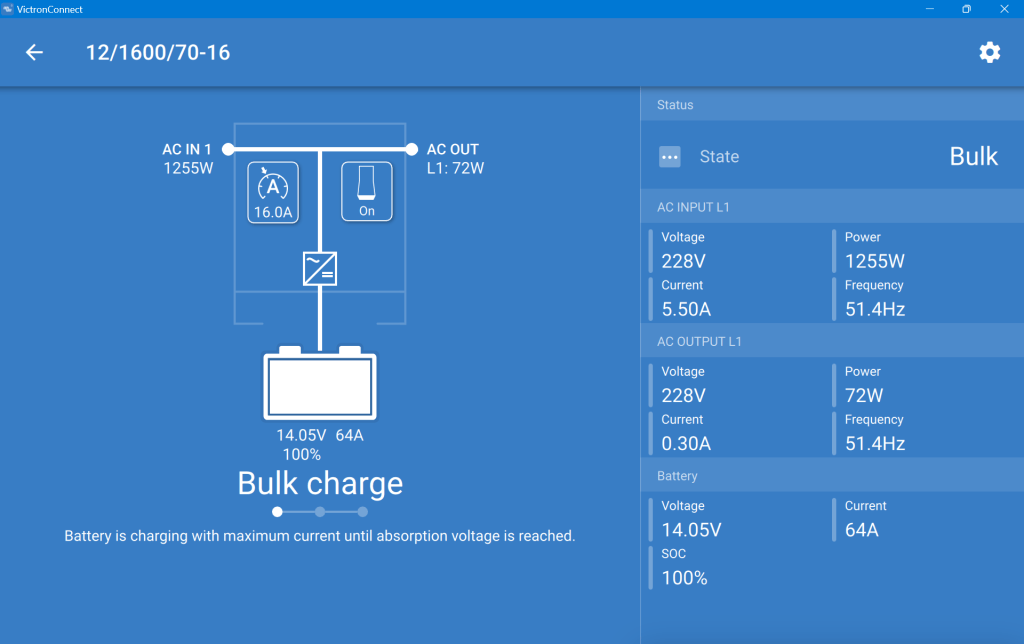

As a 24/3000 MultiPlus-II (or EasySolar-II) does only support charging of up to 70A (resulting in a nominal charging power of 24V * 70A = 1680W), we would still be 55A “short” of the desired maximum charge current of 125A. With the EasySolar-II GX or the MultiPlus-II GX there is no 24/5000 version and the MultiPlus-II 24/5000 uses considerably more power (18W vs 13W) and is way heavier (30kg vs 26kg [including MPPT charger] vs 20kg). In addition the inverter would be massively oversized as the maximum expected inverter power would be limited to 8* 3.65V * 125A = 3200W (^=4000VA), anyway.

So, I came to the conclusion the least expensive and space/cost-efficient solution would come in the form of a Victron Skylla-TG 24/50A Charger:

- Weight: 5.5kg

- Price around 500,00 GBP

- Dimensions: H 365mm * W 250mm * D 147mm

So, with the combined power of the EasySolar-II and the Skylla-TG (70A + 50A = 120A), I can now theoretically charge at 8 * 3.2V * 120A = 3072W – near the maximum supported power. As the charge current will probably reduce at around 80% SOC, my 24V battery can be charged from 40% to 80% within one hour – at a price of less than 30p per Kilowatt (or 90p the hour)!

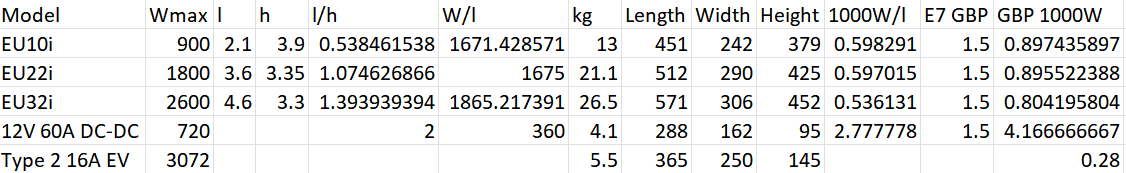

Here a comparison with some smaller generators:

- a Honda EU10i will deliver 900W with 0.538l

(around 1671W/l or 0.598l per 1000W) - a Honda EU22i will deliver 1800W with 1.075l

(around 1675W/l or 0.597l per 1000W) - a Honda EU32i will deliver 2600W with 1.394l

(around 1865W/l or 0.536l per 1000W)

If one liter of E7 costs roughly 1.50 GBP, the price per 1000W is between 0.80 GBP and 0.90 GBP.

And with a standard vehicle alternator of 100A the maximum charge current for a battery would not exceed 60A. So, a realistic amount of power to charge the battery with a running engine is around 12V * 60A = 720W. If we expect the vehicle to use 2l per hour running idle, the price for 1000W would sum up to over 4.17 GBP – not cheap.

Only the Honda EU32i comes near to the maximum charging power of 3200W/h. But the initial cost for the inverter and the price per 1000W is far beyond the cost of an additional AC charger, a Type 2 adapter and the energy cost at the EV charging station. And ideally, the energy from the EV charging station is “greener” than the energy from the vehicle or stand-alone generator.

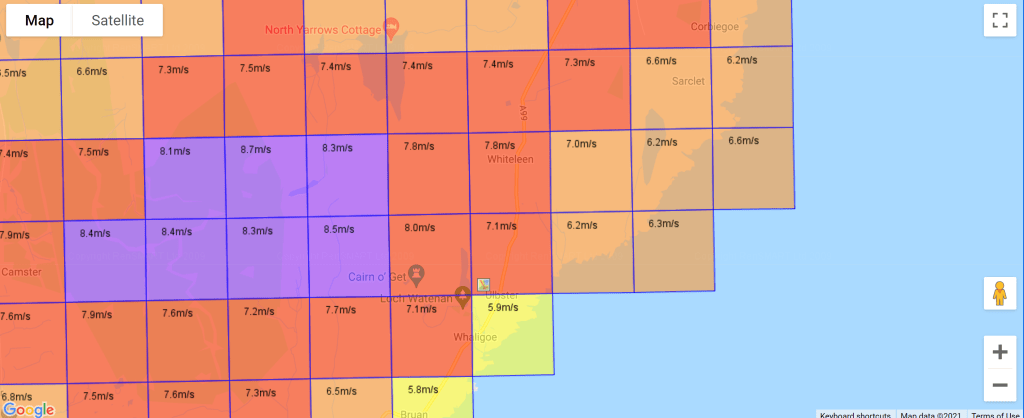

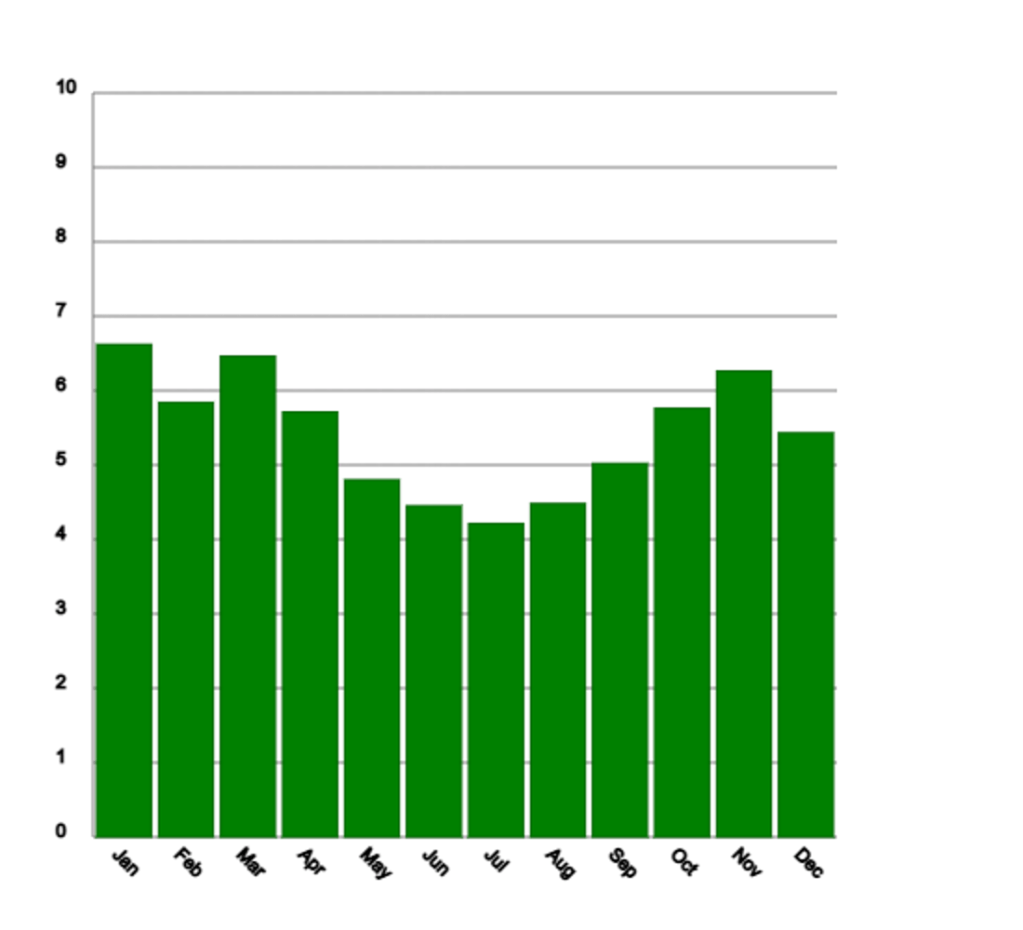

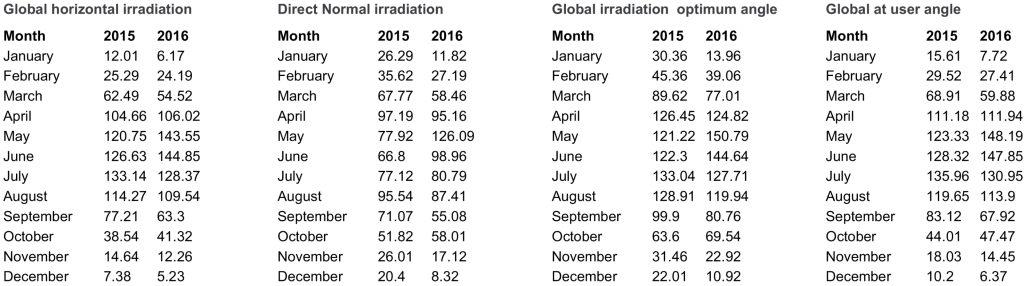

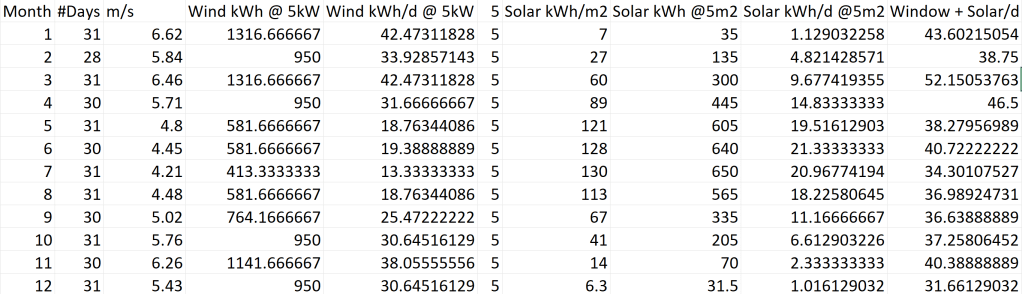

Note: I did not write about solar panels at all. The reason for this is our special “use case” where we are mainly in northern europe where during autumn and winter there are very little hours of sunlight – at a time when we need energy the most. Plus, only two of our vehicles have actually space on the roof for solar panels.

This is my current take on charging larger leisure batteries. What is your opinion on this?