It has been a while since I last wrote about what has been going on the plot. And actually, something has happened.

Let me briefly explain where we currently stand and maybe I find time to to dive in to details in additional posts.

So what happened?

- We got our Telehandler, the JCB 531-70; so we are now able to do some heavy lifting and more …

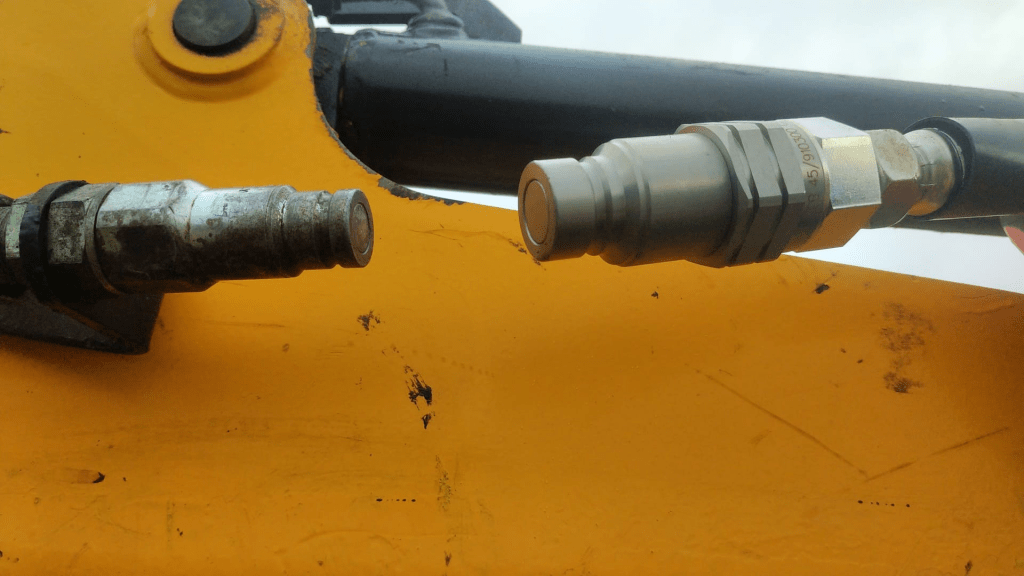

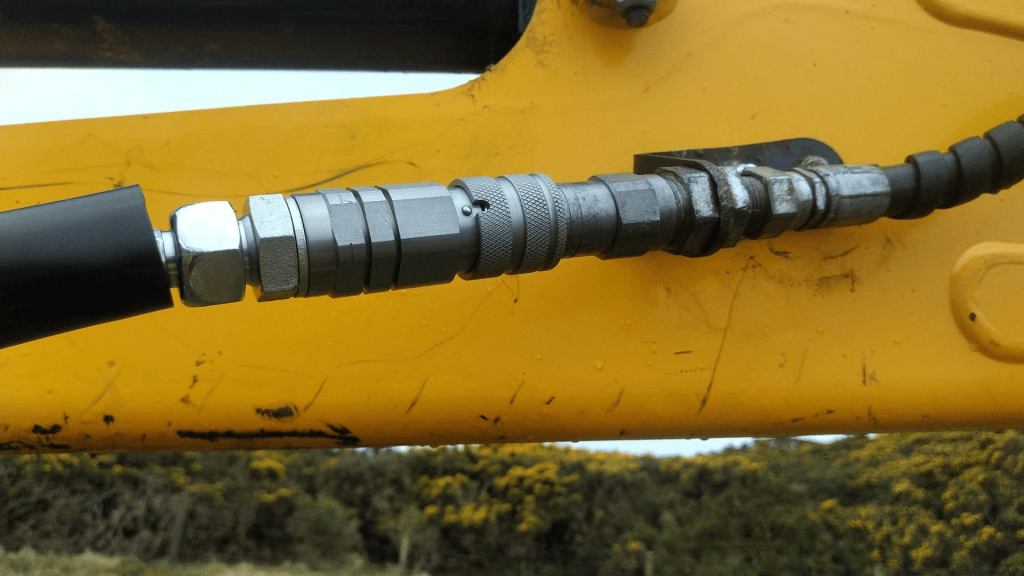

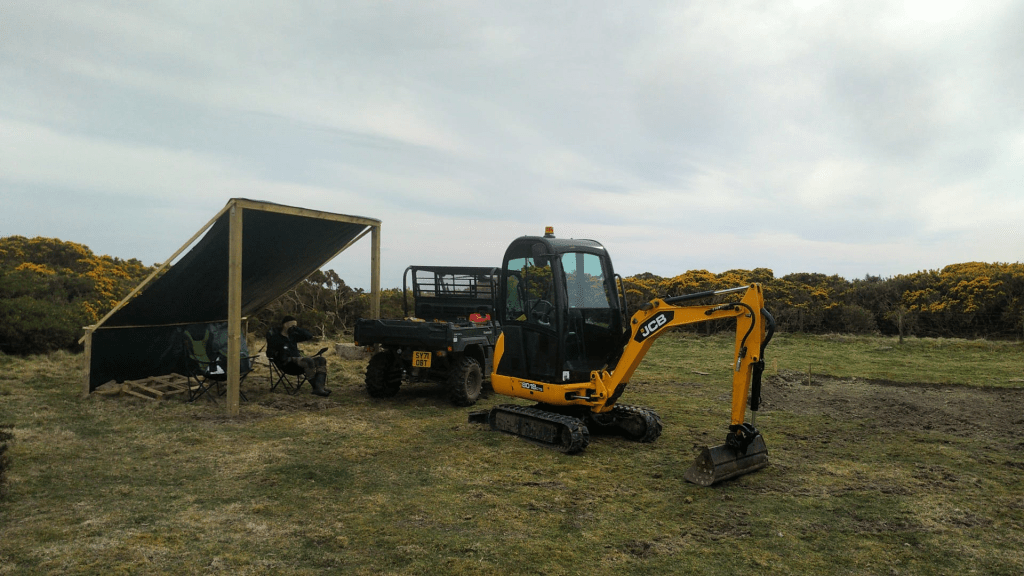

Quick note: And yet with this delivery not everything went smoothly, as the brand new machine was not working completely as expected. But we now have a new local technician from Latheronwheel who is very kind and helpful. - The digger finally got fixed. We now even have a quick-hitch, which seem to be not so “quick” (but that is a different story). We were even able to fix a loose track on the excavator. It is easy once you know …

- We also now have a 3.5t 13ft tipping-trailer with which we are able to bring more stuff to the plot (such as concrete, gravel – more on this later).

- We fixed more parts of our track to the plot (by adding stones to the ground and putting gravel on top of it). This is only a temporary fix, as the ground is still way to weak to hold the weight of the 7t Telehandler or a fully loaded trailer.

- We even now a diesel tank from which we can fuel our vehicles and machinery. And refilling it on the main road is as easy as lifting it with the forks of the Telehandler.

- Electricity is now much easier as we can run on a generator as long as we have not finished the turibine/battery set up. As the generator runs on diesel we can refill it from the same diesel tank as everything else.

- We discovered a quarry on our plot (which has not been used for probably more than 100 years. I have 2 raw short video sequences (no voice, just walking aroung) that are linked below to get a first impression. As you can see, we had to cut through a lot of gorse to actually get there. The only reason I found out that there is a quarry was, that I saw it on some older maps from the scottish national library archive. There is still some work to get done to easily access the quarry or to get some stones from it. But the good news is, that we now would not have to transport that much amount of stones from a different quarry further away.

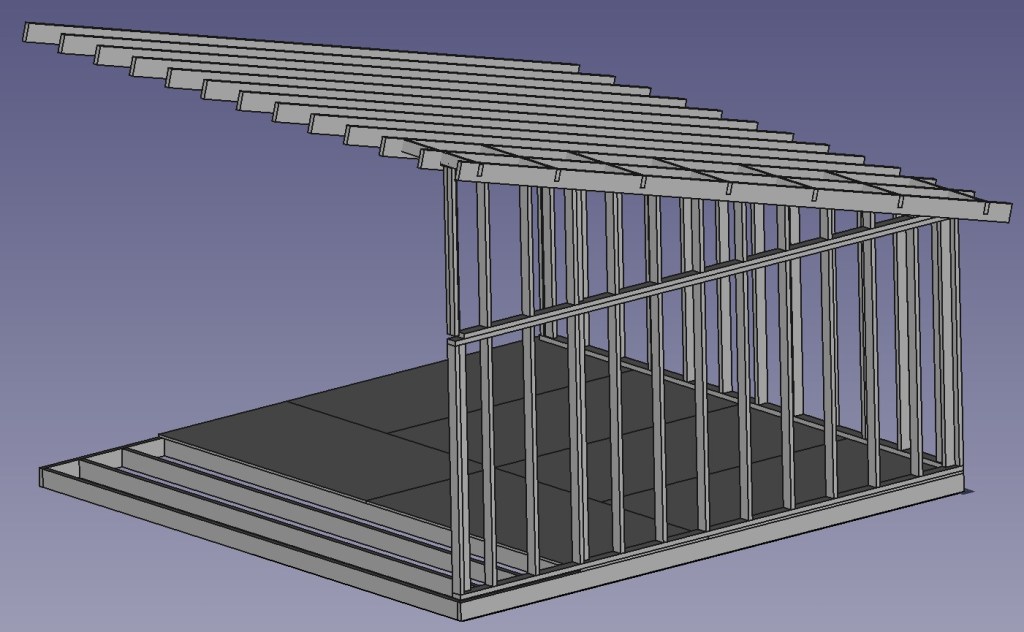

- We actually started with our shed; i.e. we did the foundation by pouring concrete for 12 pads and nearly finished the floor insulation. That actually means that the wood *finally* arrived (more than 3 months). Next time I buy the wood somewhere else and not at the Sutherland woodyard in Wick (and yes, I would link a website if they had one).

- Planning permission for entrance from the A99 and the barn is still under consideration (*everything* in the Highlands justs takes looonger).

- I got myself a pocket calculator Construction Master Pro Trig from “Calculated Industries” to at as a babel fish between the “imperial” surrounding and my “metric” mind. Now I know that 2″ 7/8 are roughly 73mm – so good!

- We cut away even more gorse (and still have to wait until autumn to be able to burn it).

- I finally admitted to myself that I will have to do a monthly trip to Inverness to be able to buy the stuff I need (the cowboys riding to the city). And here the trailer really comes in handy!

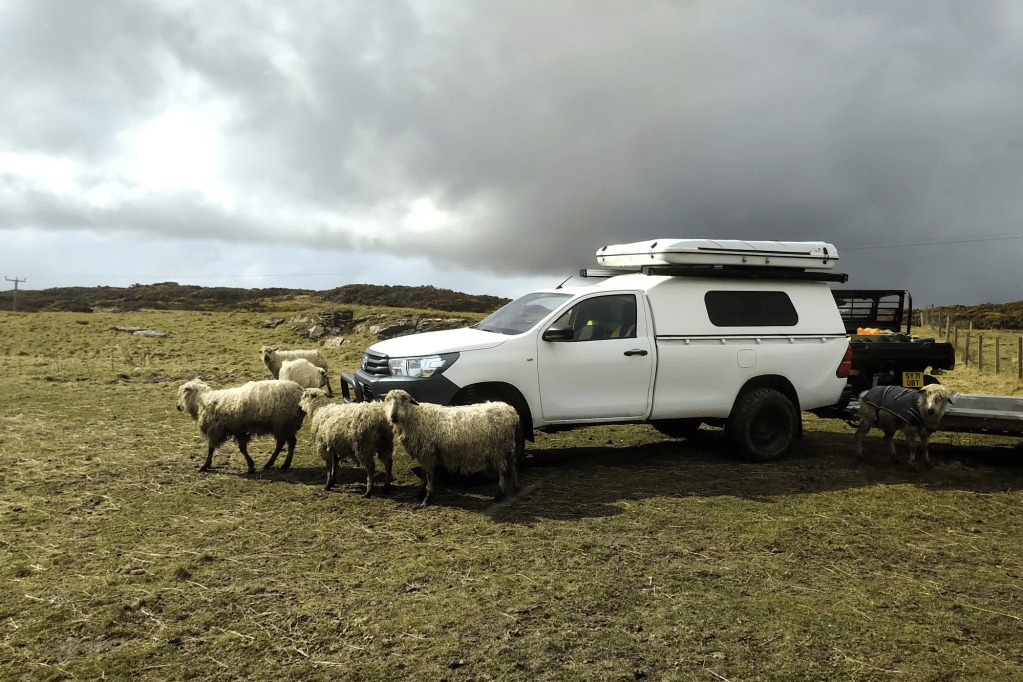

Side note: and it was actually in Inverness where I got the scaffolding poles for the turbine. No way for me to get them in Wick. - We did some sheep shearing support – first step in becoming real crofters …

So why am I writing all this? Is everything solved? Far from that.

I am probably more of writing this to remind me that though it seems that nothing really proceeds as planned and barely no progress is visible, some things are still getting done. So there is actually progress (however small it is).

Shedland

Quarry videos