The other day, I realised that I never wrote about the case build of our 16s 48V batteries, as I did for the 8s case and the 4s case. So, here it is – and I am actually describing 2 revisions as we made some adjustments.

First, the total weight of the cells alone would be roughly 16 * 5.3kg ~ 85kg. This is way beyond what a single person can – or at least should – lift. So, I deciced to split the battery into 2 separate cell blocks of 8 cells each (similar as I did split the 8s battery in the Toyota HiAce). With this approach, I would be able to:

- reuse the 8s design (including the RAKO boxes)

- be able to move or lift half a battery (which weighs roughly

53kg)

This battery has a nominal capacity of 3.2V * 16 * 280Ah = 14'336Wh and can be charged or discharge with up to 140A ^= 7'168W. We currently have 2 of these batteries running on our 3-phase setup with 3 * Victron MultiPlus-II 48/5000/70-50.

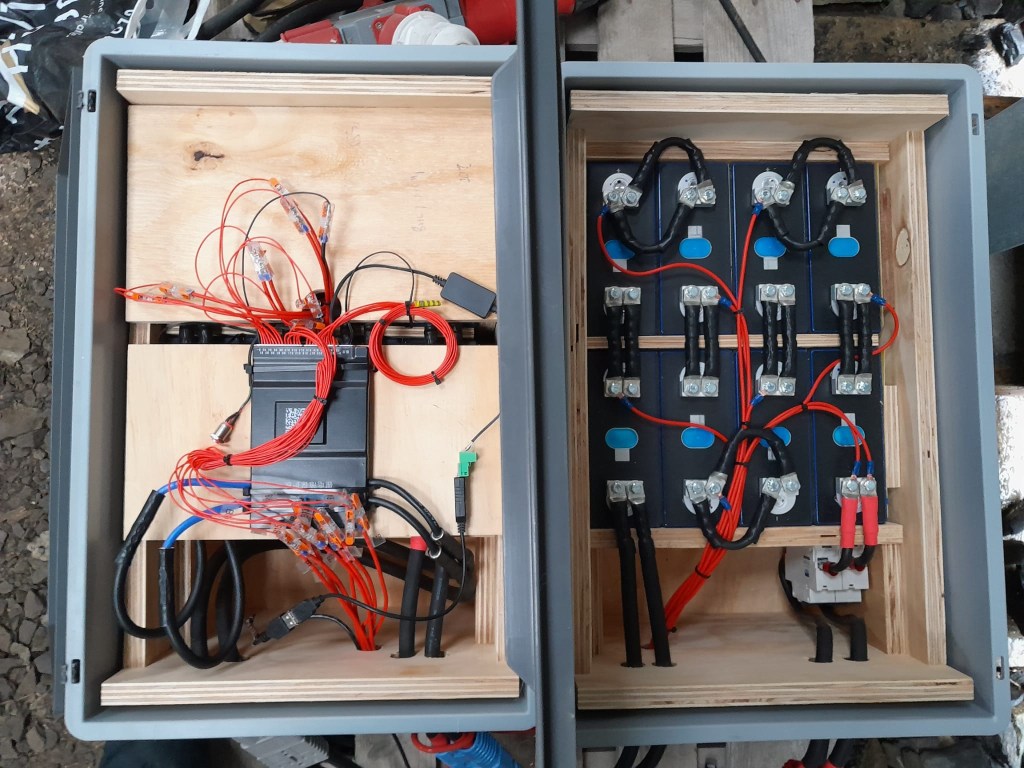

So essentially, I built 2 8s batteries with a connection cable between cells 8 and 9. The main negative and the BMS would be in one box and the main positive with the DC breakers would be in the other box. To avoid confusion, in this setup I went for coloured Anderson SB175 housings, with

- Red

2 * 35mm2H07RN-F cable main positive - Grey

2 * 35mm2H07RN-F cable main negative - Blue

Interconnecting both blocks2 * 35mm2H07RN-F cable connecting from cell 9 positive to cell 8 negative

In all cases

To connect the cells to the BMS balancer cables I extended the balancer cables with 2.5mm2 wire via WAGO 221-2411 inline splicing connectors. I then measured the increased resistance of the additional cable length and adjusted the values in the BMS configuration for cells 1 to 9.

With these inline connectors I am now able to disconnect the blocks from each other so I can move them around independently, if needed.

On the BMS, I connected a USB RS-485 TTL adapater with a USB extension cable which leads to one of the USB ports of the Victron Cerbo GX. With the help of dbus-serialbattery and BatteryAggregator I can control the DVCC settings in Venus OS.

The rest of the build is, as I already mentioned, pretty much like the 8s build.

Revision 1

Here are some images of the completed build of revision 1.

Revision 2

These are the changes I am currently making for the next revision:

- add additional connectors for the balancer cables to further facilitate the disconnection of both blocks;

- use

16mm2M6 Klauke DIN46235 compression cable lugs for the connection of the main negative (cell 16) to theB-of the BMS (only relevant to the older JK-BMS), to be able to disconnect and potentionally replace the BMS; - use a WAGO

35mm2DIN rail connector in the main negative block on cell 1/9 for the outgoing cable; - use cable glands on the external connections;

(this allows for easy disconnection and re-building the block as an 8s battery); - use ratchet straps for compressing and mounting the cells to enable easier maintainability of the cells;

- use Anderson PowerPole PP180 connectors instead of SB175, so I can use mounting plates for the PP180 and do not have dangling cables on the outside of the case

(these connectors are expensive and increase the price of the overall build by roughly60GBP).