In one of our previous articles I wrote about the Honda EU10i as a backup generator for charging batteries via a Victron MultiPlus. Now as the supply chain has stabilised, the only noticable downside of this generator, that it will set you back a 1'000+ CHF (and even 1'000+ GBP in the UK). As we plan to equip our HiAce, Hilux, 2DM and possibly our trailer with such a generator this really adds up. So, I started looking for something cheaper – but hopefully equally robust, enduring and sturdy.

The requirements were basically unchanged. We want a generator that

- is light

less than20kgincluding fuel - has a sustainable output of over

3.5A@230V

as the MultiPlus-II 48/5000/70 has a minimum AC input limit of 3.5A - in combination with a MultiPlus 1600VA and PowerAssist must be able to provide more than

2'000W

(which is already fulfilled when delivering more than 3.5A by itself) - generates more than

1'000Wh/l - must have an internal tank

- generates more than

8'500Whwith the internal tank and an additional5ltank - must be running petrol or diesel (the latter very unlikely in that weight range)

- should be quiet

the less noisy the better, no hard specs here - (optional) can be paired with another model to double the output

- must have an automatic shutdown in case of oil issues and overload

- must have an ECO mode

- manual starter

i.e. no battery needed for starting the generator - a seller with a service center from UK, CH or EU (preferrably DE/AT) for filing warranty claims if necessary

On AliExpress, eBay and Amazon there are quite some models for very little money. However, I also have very little trust (if there is such thing at all) in those product offerings.

So, when I did some modern research (i.e. googling around the internet) I came across three models:

- Hyundai HY1000Si (350 GBP)

- P1PE P1000i (300 GBP)

formally known as Position One Power Equipment (kudos to the marketing department for such an intriguing brand name) - Scheppach SG800 (200 EUR)

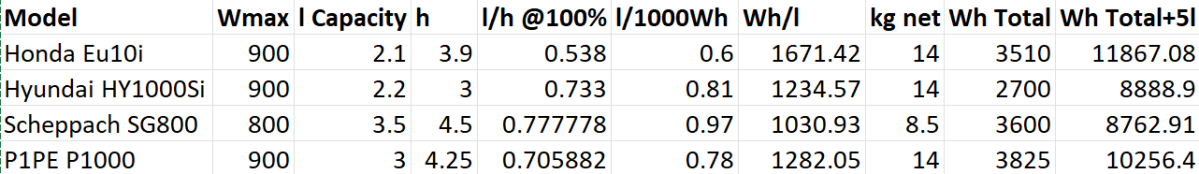

But before I go into detail here is a summary of the comparison:

Hyundai HY1000Si

This is the model I am most likely to buy (if I want to save money over buying the Honda EU10i).

Except for size, weight and price all its specs do not match the Honda EU10i (regardless of the slightly larger tank).

With a total advertised runtime of 3h it can produce 2'700W (which is the equivalent of roughly over a third of the nominal capacity of an 8s 280Ah battery – compared to nearly a half for the EU10i).

So unless we intend to use the generator only seldomly this would make a real (negative) difference in:

- usability

more frequent usage pattern, more refuelling operations - maintainability

due to more service hours and material wear-off

and efficiency

longer runtime, more fuel consumption, more labour.

Compared to the Honda EU10i (which some consider the “gold standard”) there is relatively little information to be found about this generator (especially no thorough reviews).

Further note: From the advertised information the generator comes with some tools and replacement parts and even oil (which is an advantage over the Honda).

P1PE P1000i

Not a brand I have heard from before. It is a brand in the UK sold by the same company, GenPower Ltd, that is also the distributor for the Hyundai generators. And they heavily claim to use Hyundai engines as well. So much in fact, that at first sight it seems they *are* Hyundai generators.

The data sheet is to be questioned. A total runtime of 8.5h @50% load is advertised and no mentioning of any fuel consumption at 100% load. In the data sheet a fuel consumption of 550g/kWh is mentioned. With a specific weight of 740g/l for petrol this would equate to 0.74l/kWh which is not in line with the previous statement of 8.5h of runtime at 450W which would result in 0.78l/kWh. This would only “add up” with an assumed specific weight of 700g/l. And with petrols like E7 or E10 the specific weight will more likely further increase as in reduce. Furthermore, a generator running at 100% load is not expected to be as efficient as if it was running at 50% load. I am not saying that the 40ml/h make so much of a difference (it is slightly 5% off). I just get curious when the technical data sheet more looks like a marketing brochure. So, I would rather estimate a runtime of 4h at full load which would result in 0.83l/kWh or 1204Wh/l.

As P1PE seems to use the same Hyundai engines their increased efficiency over the HY1000Si would have to be in the “inverter” or electronics part of the generator. I do not find it likely that the cheaper model would have more efficient ingredients than the Hyundai model.

Scheppach SG800

A brand I have not heard from before either. Efficiency is not its strength and as I did not find it anywhere stocked, I merely list it here as an interesting option because of its form factor.

With only 800W this generator seems to be on the weaker end. But with only 8.5kg and a 3l tank it makes it up for its lack of efficiency and output capacity.

This might be an option where one really only rarely uses the generator. And then only to charge a battery (which is exactly what we aim for).

The price is debatable as I could not find it anywhere ready for order.

Summary

The choice for these small generators is rather small. If we were open for larger and heavier models the 2'000W range of inverters would provide a much broader selection (also with a higher price tag).

So, to come to a conclusion: it’s mainly price over efficiency and loudness. Is the spending of 2.5 times more justified for a generator which I only want to use in edge cases? For our use case, probably not.